The last step of the production is finishing, a precious and fundamental detail, in order to guarantee an optimal technical and esthetic level of the product. The finishing department is organized to treat all the metallic materials processed internally, giving each of them the appropriate finish to enhance its features. For instance, inox steel finishes, either polished or glazed, are obtained through specific zirconium wheels and belts, with no need to paint.

The other metals, instead, are degreased in ultrasound tanks and then moved into the pressurized painting cabin. The quality of the paints used, along with the 150°C oven cooking, guarantee an excellent resistance throughout the years, even in brackish areas (resistance tests up to 300 hours in saline haze).

The cleaning and dressing processes are accomplished lengthways, to eliminate the helix stains on the clean tubes with rotating machines.

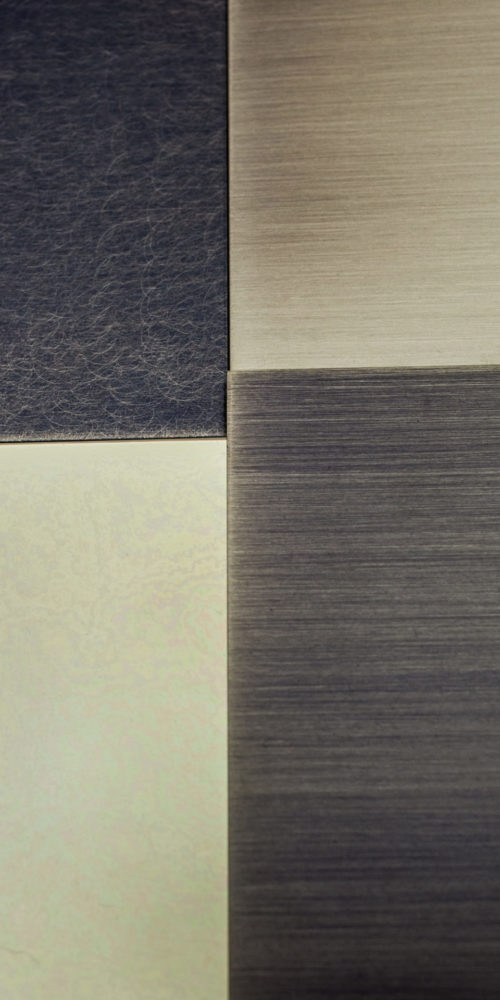

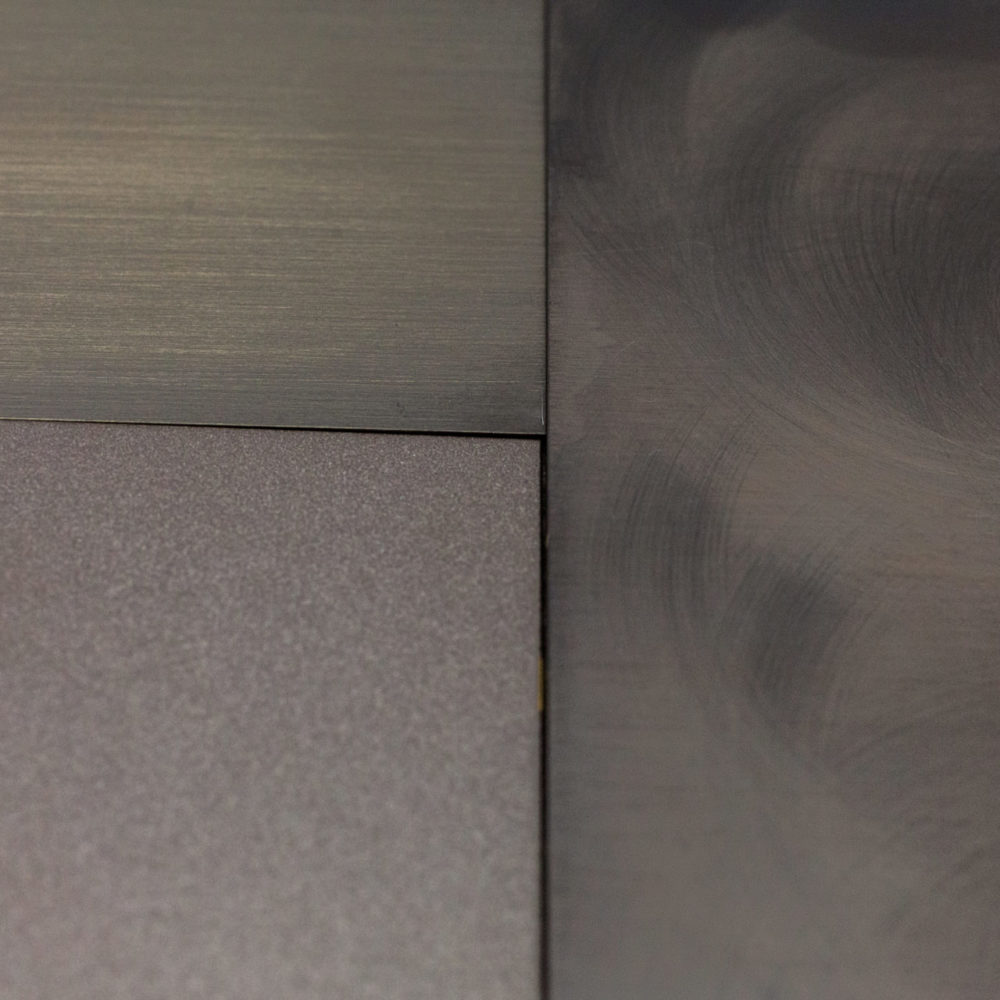

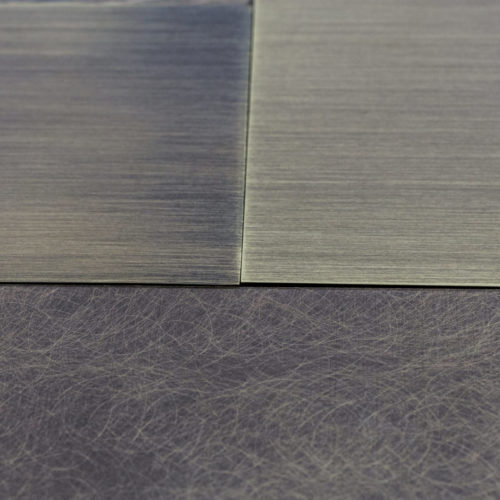

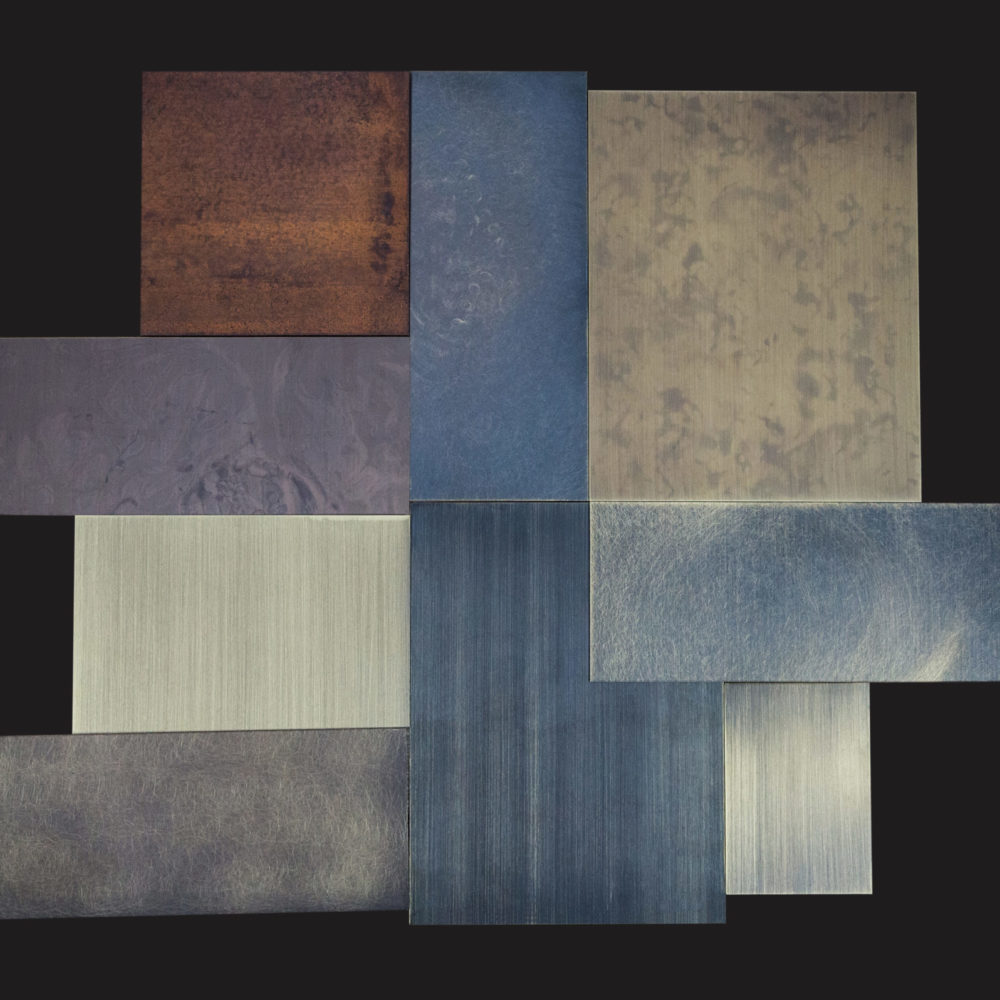

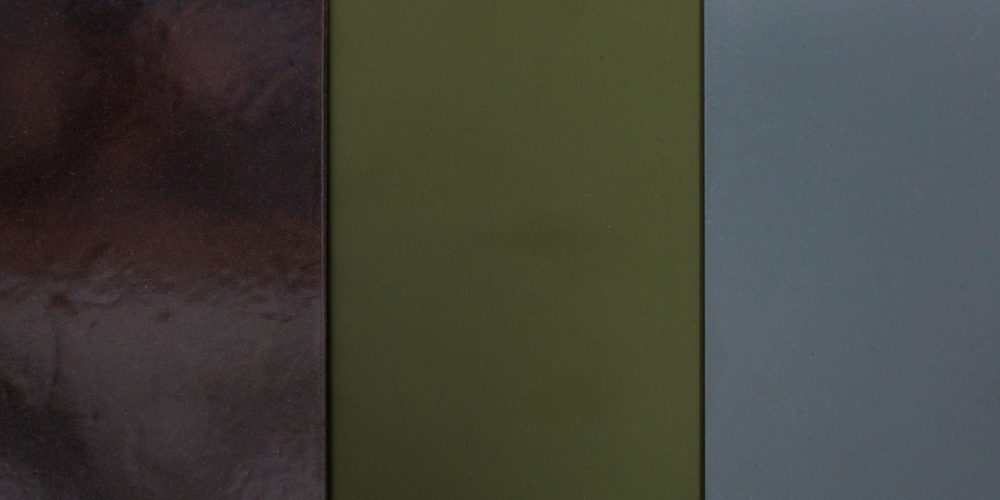

The key strength of Cantù Ottone’s finishes is brass bronzing, which gives the material an antiqued color. Thanks to our technicians’ experience, we are able to offer various bronzing color palettes, in order to satisfy every customer’s demand, guaranteeing a unique quality product.